Melt filters by Laser Filters,is an advanced recycling technology for eliminating impurities from recovered plastic.

Two different filtering devices, each on its own extruder, are used in an existing procedure to remove unwanted particles from molten plastic. After the resin has been through the first machine, it is allowed to cool before being divided into granules and sent through the second machine to get rid of smaller particles. The frequent cooling and heating steps in this method might deteriorate the characteristics of the plastic and are expensive in terms of equipment costs.

A second technique includes running two distinct filtering devices in line while the molten resin is being processed. The technology is noted to have “the forces and the full length of the passage… are so high that they substantially degrade the plastic substance.”

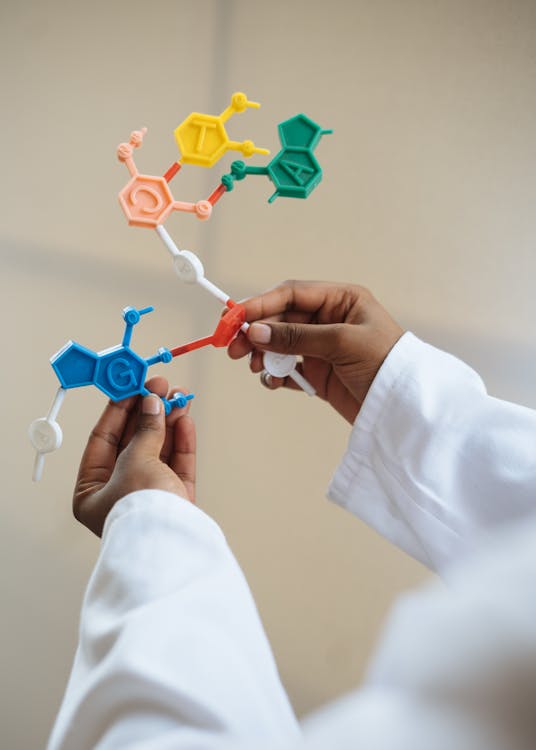

The device created by GP-Technology consists of a hollow body with several filters organized sequentially and an inlet and an outlet for molten resin. The filters have spinning scrapers that are powered by a driving shaft that is externally operated. Filtered debris is removed by scrapers and directed out of the device through a driveshaft part with a hollow section.

Each filter is made up of a metal perforated sheet that rests on a perforated disc or plate that is firmly linked to the hollow body. The sheet rests against the robust disc because it cannot sustain the system’s operating pressures. Because the holes in the filters are varied sizes, the first filter captures bigger impurities while the following filters capture smaller particles.

The driveshaft rotates the scrapers to clear any debris that might be clogging the filters if the pressure of the molten plastic exceeds a specific value, which is a useful aspect of the innovation. This stops the melt from melting at pressures that are too high. The technology uses a method that “the driveshaft can be set in rotation on command independent of the pressure attained by the molten material, continuously or according to a sequence or time intervals, or as a result of expected events.”

Due to its small size, low cost, protection of the plastic’s physical qualities, and ease of maintenance, the invention addresses the shortcomings of existing methods.

Depolymerization is a recycling technology that is used as a method of recycling used plastics by dissolving them into chemicals like light olefins, benzene, toluene, and xylene also used in the filed of melt filters technology.

With the novel technique, the polymers are first dissolved in an aromatic-rich solvent before being catalytically cracked in a reactor. Polyethylene, polyethylene terephthalate, polystyrene, polypropylene, polyvinyl chloride, polyamide, polycarbonate, polyurethane, polyester, natural rubber, synthetic rubber, and mixtures of these polymers can all be processed using this technique.

The dissolved polymer solution has a residence period of no longer than one second in one embodiment of the invention, which operates the reactor at temperatures between 1,022 F and 1,202 F.

Catalytically cracking the dissolved polymer solution further involves, in at least one embodiment, catalytically cracking the solution in a riser fluid catalytic cracker reactor.

In comparison to previous depolymerization techniques such delayed coking, pyrolysis, gasification, and liquefaction, the invention offers advantages since it generates less waste, is more cost-effective, and doesn’t introduce impurities like sulfur and nitrogen.

When conventional recycling is not cost-effective, the company promotes the development as an alternative to landfilling or incineration.